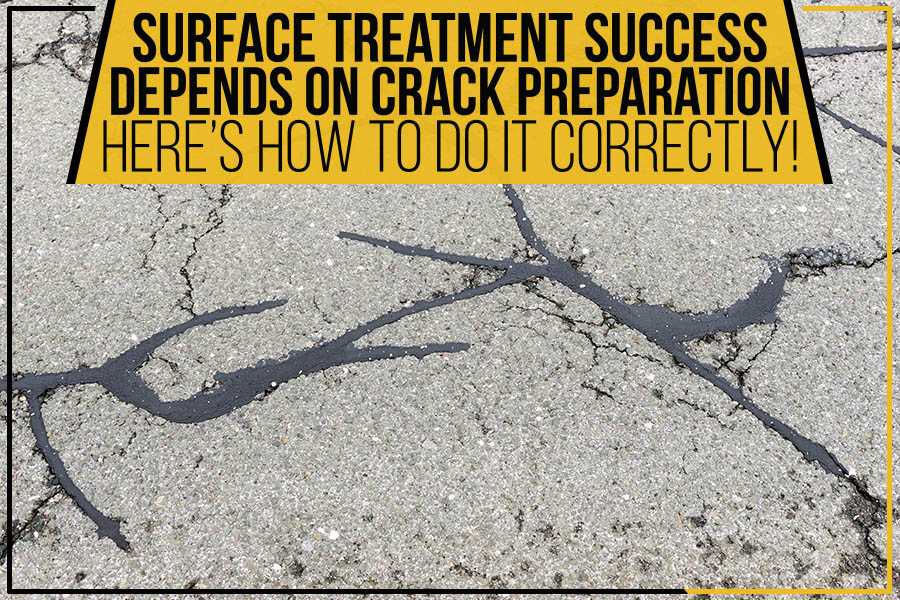

Are you looking for a surface treatment that will last? If so, you need to ensure that the crack preparation is done correctly. Many people mistake not preparing the surface properly, which leads to problems down the road. In this blog post, PowerSurge Plus LLC will discuss how to prepare the surface correctly to get the most out of your surface treatment!

How do cracks affect the surface treatment?

Pavement overlays and preservation treatments are often used to restore surface course qualities such as smoothness, friction, and aesthetics or give structural support to an existing pavement.

However, suppose there is a crack on the existing pavement. In that case, these faults will frequently occur, resulting in premature pavement collapse in the form of cracks and deformations.

To extend the usable life of an overlay, you should hire a professional to fill, rebuild or seal the failing areas of existing pavements.

What to do with cracks?

Crack sealing is often done using liquid asphalt, cutbacks, or emulsions. Crack sealing is perhaps the single most significant maintenance task as this preventative maintenance reduces asphalt degradation; consider a crack to be a scrape on your skin. It becomes infected and spreads if left untreated, causing a much bigger problem.

Where can you do crack sealing?

Crack sealing keeps a securely sealed crack only as long as the pavement is immobile and structurally stable. It is necessary to reseal your surface every year, especially in high-temperature conditions where expansion and contraction occur. Sealing and filling should only be done on dry surfaces and when the temperature is above 40 degrees Fahrenheit. Colder temperatures cause the pavement to contract, allowing the crack to expand and fill correctly. Traffic should be avoided on the sealed fractures until the sealant has dried.

How does crack sealing work?

It includes routing, a technique performed before cracks are sealed. Routing is done with a machine that extends the cracks to 14″ wide, creating a reservoir for the rubberized crack sealer to sit in. Workers wipe out the fissures to provide the best possible adhesion.

The above procedure guarantees that the rubber thoroughly penetrates the fracture and adheres to the existing pavement. In comparison to inserting rubber directly into existing, non-routed fractures, it helps establish a waterproof barrier to prevent leaks.

Other methods:

If the existing pavement has many fine cracks but is still structurally sound, you can apply a general bituminous surface treatment (BST) or slurry seal rather than filling each crack. It is a more cost-effective method.

Excessive crack sealing should be avoided. Other treatments, such as thicker overlays or milling, interlayer or surface treatments in combination with an overlay, may be more suited if the sealant quantity is larger than 5,000 lbs. per lane mile.

PowerSurge Plus LLC is a professional asphalt repair company in Philadelphia, PA; we provide timely and effective services to prevent pavement degradation from worsening, hence avoiding surface pavement breakdown and costly repairs.